loaction:Home → Solution → thermal pad

Thermal pad has good thermal conductivity and high level of pressure resistance, is to replace thermal grease replacement products, the material itself has a certain degree of flexibility, good fit between the power device and the cooling aluminum sheet or machine shell to achieve the best thermal conductivity and heat dissipation purposes, in line with the 21st century electronic industry requirements for thermal materials, It is the best product to replace the binary heat dissipation system of thermal conductive silicon grease paste and mica sheet. In the industry, it can also be called thermal conductive silicone sheet, thermal conductive silicone pad, thermal conductive silicone pad, insulating thermal conductive sheet, soft heat dissipation pad and so on.

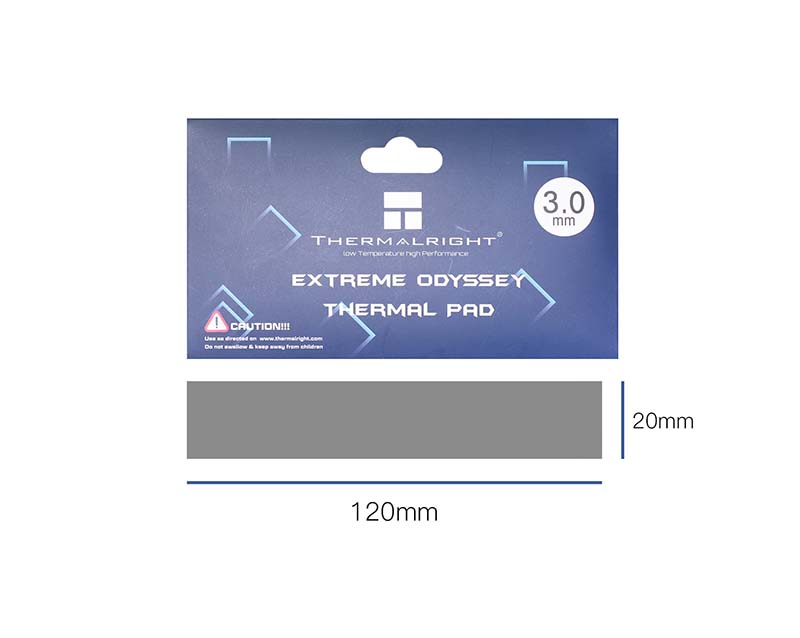

Thermal pad has a certain degree of flexibility, excellent insulation, compressibility, natural surface viscosity, specially designed for the use of gaps to transfer heat, can fill the gap, complete the heat transfer between the heating part and the heat dissipation part, such products can be arbitrarily cut, conducive to meet the automatic production and product maintenance. The process thickness of the silicone thermal insulation pad varies from 0.5mm to 5mm, each 0.5mm plus, that is, 0.5mm 1mm 1.5mm 2mm to 5mm, special requirements can be increased to 15mm, specially produced for the design of using the gap to transfer heat, which can fill the gap, complete the heat transfer of the heating part and the heat dissipation part, and also play a shock absorption The function of insulation and sealing can meet the design requirements of miniaturization and ultra-thin of social equipment, and it is a new material with great process and usability and is widely used in electronic and electrical products.

手機(jī)掃碼訪問